For standard models, the delivery lead time is about 20 days .

This system is designed specifically for medium-scale sponge production, making it ideal for producing a wide range of products in small to medium batches.

The Automatic Box Foaming Machine is designed for efficient and precise foam production, ensuring uniform density and high-quality output for various industrial applications.

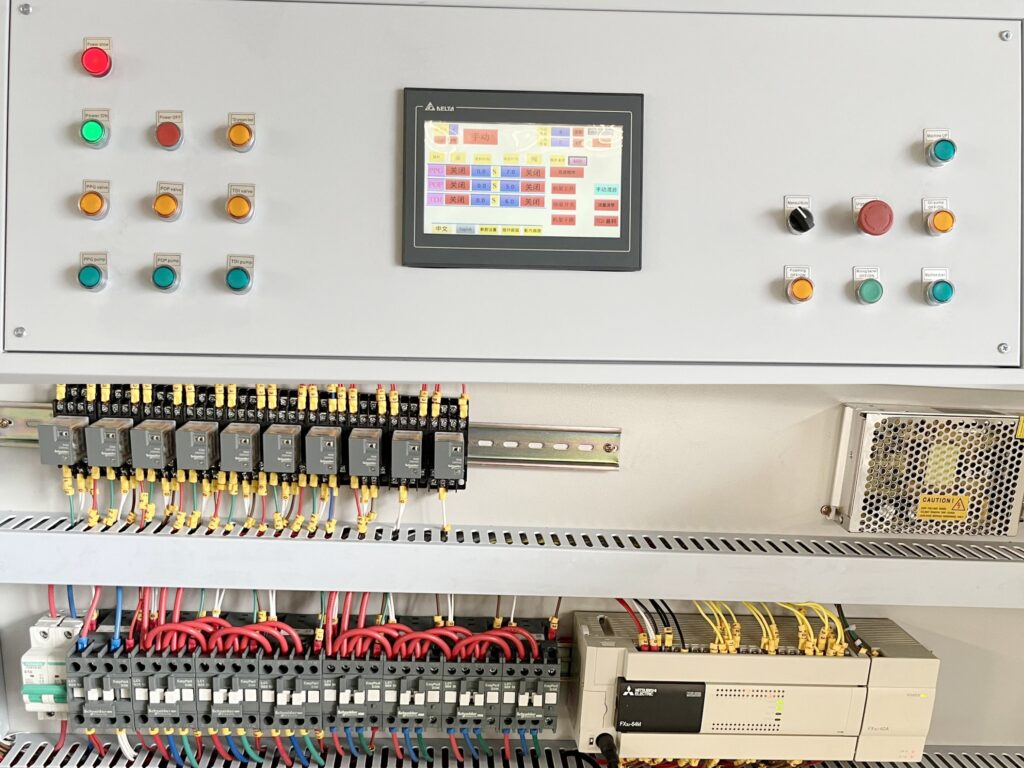

The system is equipped with a sophisticated PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) control system, allowing for precise management and monitoring of the production process. The PLC ensures automated control of key functions, reducing the potential for human error, while the HMI provides operators with an intuitive interface to oversee operations, make adjustments, and access real-time data. This combination improves efficiency, enhances user control, and facilitates smooth operation of the entire production line.

For enhanced automation and convenience, the system features automatic door opening and closing for the mixing barrel. This function eliminates the need for manual intervention when loading or unloading materials, improving overall workflow efficiency. The automatic mechanism ensures that the barrel is sealed securely during the mixing process, preventing material spillage and contamination while optimizing time spent on each batch.

The raw material tanks are equipped with an advanced temperature control system to maintain optimal conditions for the materials used in the production of foam. This feature is crucial in ensuring the stability and consistency of the foam, as temperature fluctuations can affect the quality and properties of the final product. By keeping the materials within the desired temperature range, the system ensures a uniform mixture and high-quality foam production, reducing waste and improving product consistency.

This machine is designed for producing polyurethane foam with a density range of 8-80kg/m³. It utilizes advanced technology for raw material mixing, foaming, and forming, and is equipped with an intelligent touch screen control system. This allows users to easily manage and adjust various formulas to meet the production requirements of different products. The production line has both fully automatic and manual control functions, making it easy to operate. It is widely used in industries such as furniture, packaging, automotive, aviation, and more.

Working Principle:

First, the raw materials are fed into the raw material tanks. The formula is operated on the control panel, and parameters are set. The raw materials are then pumped into the mixing barrel. After mixing, the materials are poured into molds, where they slowly cure for 2-3 minutes and form into foam. After foaming, the foam can be demolded in about 5 minutes, and then left to naturally cure and air dry for approximately 8 hours.

| Model | SR-SAF01 |

|---|---|

| Foaming group | 3groups |

| Foaming width | 1550-2050mm |

| Foaming length | 1250mm |

| Foaming density | 8-80kg/m3 |

| Max.output | 260L/min |

| Mixing head power | 11KW |

| Machine external size | L10000×W7000×H3500mm |

SR Machines specializes in providing innovative sponge machinery solutions, offering precision, reliability, and efficiency. With expert design, global support, and customer-centric solutions, we enhance production performance and long-term durability.

Continuous R&D investment brings advanced foam processing technology daily.

24/7 technical assistance with rapid parts delivery guarantee.

In-house design and manufacturing delivers exceptional value-driven solutions.

Over ten years advancing foam machinery manufacturing excellence.

Complete foam equipment range from production to packaging solutions.

Comprehensive support from initial consultation through ongoing maintenance.

We provide cutting-edge foam machinery designed for precision, efficiency, and long-lasting durability. Backed by deep industry expertise, global support, and a strong focus on customer-centric solutions, ensuring optimal performance and satisfaction.

Discover top-tier inverters in our product section, each crafted for maximum efficiency and reliability in any setting.

Explore expert insights, industry trends, and the latest updates on innovative sponge machinery solutions, designed to optimize production efficiency, improve performance, and drive sustainable growth in manufacturing processes.

Uncover efficient packing machines designed to streamline sponge product packaging and logistics.

Discover how modern cutting machines are revolutionizing precision in sponge manufacturing processes.

Learn about eco-friendly re-bonding solutions that turn sponge waste into valuable products.

Explore the latest advancements in sponge foaming machinery enhancing production efficiency and product quality.

For standard models, the delivery lead time is about 20 days .

Services include installation and commissioning, technical training, spare parts supply, and remote support.

Yes, formula design services are available.

The entire process from raw material mixing to foaming completion takes about 8-10 minutes per batch. Curing time may vary based on the formula.

Yes, installation manuals, pictures, and videos are provided, and many customers handle the installation themselves.

It typically requires around 100 square meters of operational space, depending on the model.

Yes, on-site training is provided after installation, covering foaming techniques for high, medium, and low-density foams.

The main raw materials include PPG, TDI or MDI, MC, T9, Silicone, A33, H2O, etc.

Yes, the number of components can be adjusted based on the type of sponge being produced.

Yes, by adjusting the formula, the machine can produce foams with densities ranging from 8 kg/m³ to 80 kg/m³.

Yes, molds can be swapped to accommodate various sponge sizes and shapes

Typically, the machine can produce about 3 cubic meters per cycle, depending on the equipment specifications and mold size, which can be customized.

The box foaming machine is suitable for producing standard PU foam, high-density foam, memory foam, etc., depending on the equipment configuration and raw material formulation.

Yes, we provide on-site installation, commissioning, training, and maintenance services to ensure smooth operations for our clients.

You can reach us via email at sr@srmachine.com or by phone/WhatsApp at +86-13450688517. Our factory is located in Dongguan City, Guangdong Province, China.

Our factory follows strict quality control measures, uses advanced technology, and adheres to certifications such as ISO9001:2015 and SGS/CE standards.

Absolutely! We design and produce tailored solutions to match your specific production requirements.

We specialize in foam machinery, including sponge foaming machines, cutting machines, re-bonding machines, and other custom-designed equipment to meet industry needs.