Yes, training is provided upon equipment delivery to ensure operators are fully capable of using and maintaining the machine.

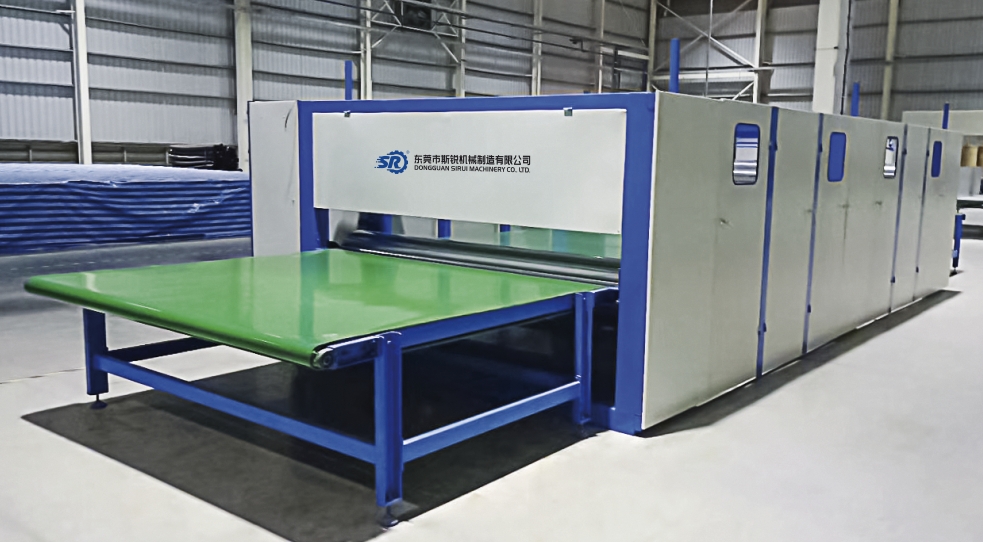

Explore the Exhaust Pressing Foam Machine in action, showcasing its ability to improve foam structure and quality through efficient air removal and pressing processes for industrial use.

The SR-YM01/YM02 Exhaust Pressing Foam Machine is designed to enhance foam quality by pressing and eliminating internal air pockets, resulting in improved density and durability. This process is essential for producing high-quality foam products used in various applications.

Working Principle:

This method ensures that the foam achieves the desired physical properties, meeting stringent quality standards for various industrial uses.

| Model | SR-YM01 | SR-YM02 |

|---|---|---|

| Pressure sponge size | 2300MM | 2300MM |

| Total power | 3.7KW | 20kw |

| Thickness | 0-1200MM | 0-1200MM |

| Speed | 0-60M/MIN | 0-60M/MIN |

| Roll dia | 300MM | 300MM |

| Conveyor roller frame size | W2300*L2000MM | W2300*L2500MM |

| Machine external size | L5000*W3500*H1600MM | L16500*W3800*H2000MM |

SR Machines specializes in providing innovative sponge machinery solutions, offering precision, reliability, and efficiency. With expert design, global support, and customer-centric solutions, we enhance production performance and long-term durability.

Continuous R&D investment brings advanced foam processing technology daily.

24/7 technical assistance with rapid parts delivery guarantee.

In-house design and manufacturing delivers exceptional value-driven solutions.

Over ten years advancing foam machinery manufacturing excellence.

Complete foam equipment range from production to packaging solutions.

Comprehensive support from initial consultation through ongoing maintenance.

We provide cutting-edge foam machinery designed for precision, efficiency, and long-lasting durability. Backed by deep industry expertise, global support, and a strong focus on customer-centric solutions, ensuring optimal performance and satisfaction.

Discover top-tier inverters in our product section, each crafted for maximum efficiency and reliability in any setting.

Explore expert insights, industry trends, and the latest updates on innovative sponge machinery solutions, designed to optimize production efficiency, improve performance, and drive sustainable growth in manufacturing processes.

Uncover efficient packing machines designed to streamline sponge product packaging and logistics.

Discover how modern cutting machines are revolutionizing precision in sponge manufacturing processes.

Learn about eco-friendly re-bonding solutions that turn sponge waste into valuable products.

Explore the latest advancements in sponge foaming machinery enhancing production efficiency and product quality.

Yes, training is provided upon equipment delivery to ensure operators are fully capable of using and maintaining the machine.

No, it will not affect the sponge's elasticity. In fact, it will enhance its softness and comfort.

Yes, the machine can be customized according to customer requirements, including processing size, compression pressure range, and other functions.

The machine uses high-pressure compression and mechanical extrusion to forcibly expel air from the closed-cell sponge, disrupting its structure and converting it into an open-cell structure.

The warranty period is 1 year, during which any faults caused by non-human factors will be repaired free of charge.

The machine can achieve over 95% removal of closed cells.

Yes, after removing the closed cells, the sponge's water absorption and breathability will significantly increase.

Yes, 24/7 after-sales support is available, including on-site repairs and remote technical assistance.

It is primarily used to remove the closed-cell structure of the sponge through compression and air extraction, improving its breathability and softness.

Closed-cell sponge has isolated internal air bubbles, making it sealed and causing poor breathability. Removing the closed cells significantly improves the sponge's breathability, softness, and water absorption, making it more suitable for applications like mattresses, sofa cushions, or sound-absorbing materials that require better air permeability.

Yes, we provide on-site installation, commissioning, training, and maintenance services to ensure smooth operations for our clients.

You can reach us via email at sr@srmachine.com or by phone/WhatsApp at +86-13450688517. Our factory is located in Dongguan City, Guangdong Province, China.

Our factory follows strict quality control measures, uses advanced technology, and adheres to certifications such as ISO9001:2015 and SGS/CE standards.

Absolutely! We design and produce tailored solutions to match your specific production requirements.

We specialize in foam machinery, including sponge foaming machines, cutting machines, re-bonding machines, and other custom-designed equipment to meet industry needs.