To clean the crusher, turn off the power and use a brush or air gun to remove the foam debris. Regularly clean the feed and discharge ports and the screen to ensure they are free of blockages.

Discover the ultimate solution for high-efficiency, precision-engineered crushed sponge production. Our state-of-the-art Crushed Sponge Production Line is designed to deliver unmatched performance, durability, and consistency.

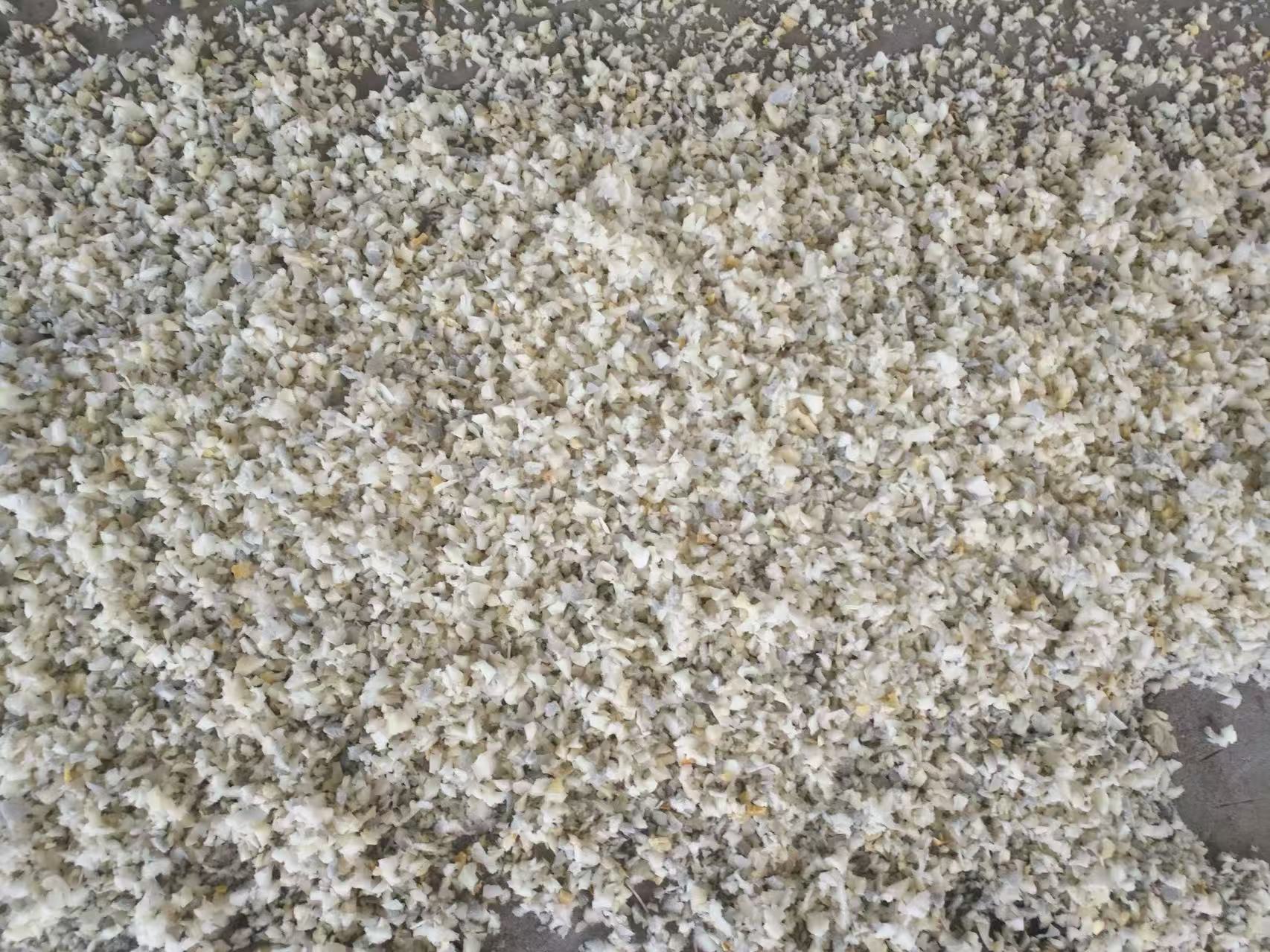

The SR-C03 Crushing Foam Machine is specifically designed to handle foam scraps, cloth waste, and thrums, efficiently converting them into granules for reuse. This machine is essential for large-scale recycled foam production lines, providing a reliable solution for processing both hard and soft materials. Equipped with an advanced cutting system, it features four rows of fixed knives and three rows of rotating knives, delivering consistent and effective crushing performance.

The machine incorporates a cold water circulation system that ensures the cutting components remain cool during operation, enhancing productivity and extending the lifespan of the blades. The particle size of the granules can be adjusted by changing the screen mesh to fit various applications, making this machine versatile for industries such as furniture manufacturing, packaging, and re-bonded foam production.

Cutting System: The rotating knives crush the materials into smaller pieces.

Granule Sizing: The crushed material passes through a customizable screen to control the granule size.

Discharge: Granules are discharged, ready for further processing or packaging.

This crushing foam machine is designed with user convenience in mind. It features noise-reduction technology to minimize sound during operation and is equipped for easy maintenance with clear access points for cleaning and blade replacement. Its robust construction ensures durability, even under heavy-duty use.

| Model | SR-C03 |

|---|---|

| Output | 500-1200kg/h |

| In size | 650×500mm |

| Rotary diameter | 380mm |

| Rotary cutter | 3 line×1 set |

| Stationary cutter | 4 line×1 set |

| Mesh size | 8-40mm |

| Total power | 35.5KW |

| Machine external size | L2250×W1850×H1800mm |

SR Machines specializes in providing innovative sponge machinery solutions, offering precision, reliability, and efficiency. With expert design, global support, and customer-centric solutions, we enhance production performance and long-term durability.

Continuous R&D investment brings advanced foam processing technology daily.

24/7 technical assistance with rapid parts delivery guarantee.

In-house design and manufacturing delivers exceptional value-driven solutions.

Over ten years advancing foam machinery manufacturing excellence.

Complete foam equipment range from production to packaging solutions.

Comprehensive support from initial consultation through ongoing maintenance.

We provide cutting-edge foam machinery designed for precision, efficiency, and long-lasting durability. Backed by deep industry expertise, global support, and a strong focus on customer-centric solutions, ensuring optimal performance and satisfaction.

Discover top-tier inverters in our product section, each crafted for maximum efficiency and reliability in any setting.

Explore expert insights, industry trends, and the latest updates on innovative sponge machinery solutions, designed to optimize production efficiency, improve performance, and drive sustainable growth in manufacturing processes.

Uncover efficient packing machines designed to streamline sponge product packaging and logistics.

Discover how modern cutting machines are revolutionizing precision in sponge manufacturing processes.

Learn about eco-friendly re-bonding solutions that turn sponge waste into valuable products.

Explore the latest advancements in sponge foaming machinery enhancing production efficiency and product quality.

To clean the crusher, turn off the power and use a brush or air gun to remove the foam debris. Regularly clean the feed and discharge ports and the screen to ensure they are free of blockages.

The blade replacement cycle depends on the hardness of the foam material and the frequency of crushing. Typically, the blades should be checked for wear every 1000-1500 hours of operation, and if the blades are severely worn, they need to be replaced.

The warranty period is 1 year, during which free repairs, parts replacements, and other services are provided.

Yes, the size of the particles can be controlled by adjusting the screen mesh of the equipment.

If the equipment experiences a fault, you can contact us for technical support, remote diagnosis, or we can dispatch technicians for on-site repairs.

The foam crusher is suitable for PU foam, leather, hard bottom leather, edge leather, fabric, and other materials.

The production capacity is between 500-1200kg/h

Yes, the crusher generates some noise during operation. However, it is equipped with noise-reducing devices that effectively reduce the noise level.

The after-sales service includes equipment installation and commissioning, operator training, routine maintenance, spare parts supply, and technical support. Long-term after-sales service is provided.

Yes, we provide on-site installation, commissioning, training, and maintenance services to ensure smooth operations for our clients.

You can reach us via email at sr@srmachine.com or by phone/WhatsApp at +86-13450688517. Our factory is located in Dongguan City, Guangdong Province, China.

Our factory follows strict quality control measures, uses advanced technology, and adheres to certifications such as ISO9001:2015 and SGS/CE standards.

Absolutely! We design and produce tailored solutions to match your specific production requirements.

We specialize in foam machinery, including sponge foaming machines, cutting machines, re-bonding machines, and other custom-designed equipment to meet industry needs.