The cutting speed is relatively fast, with the ability to complete several meters of cutting length per minute. The exact speed varies based on the foam material and thickness.

![{"data":{"capability_key":[],"capability_extra_v2":{},"os":"ios","enter_from":"enter_launch","appversion":"11.5.0","filterId":"","pictureId":"1116DCA8-A67C-4314-88BA-CEB32C16FBDE","product":"retouch","alias":"e1DZnonLaBpSfrDIxPwZnsdrOpcKeZSGehnud43fkR6JftUQBIOGTv5DEcsU9H/ozHTryucFC7ApRuRTt40+EwUb6IfDLBv+tjp7NGrAyW0YocF+/qComnUUeapsQBsGbHurTi19DdXHB5nklhaGuj818PpQZPbTEv7MqhZrT+ziilwiKtw6fSyuRyaK8aMjLGVUHl76ICwSNqnOxmc8/smKv1IwjDUnMvEJUziGK+e8t9ENTO9iWnnVfEiJHNJxdemySodJ8/M7UeIK7wgCSSfb5OCizzhCARMKE+9/t06wsM0ohrmxyo+3kZju/2TUqUno2q95mk8u2S4sV7gK9g==","imageEffectId":"","playId":"","stickerId":"","infoStickerId":"","activityName":""},"source_type":"douyin_beauty_me"}](https://srfoaming.b-cdn.net/wp-content/uploads/2024/11/2-1-scaled.jpg)

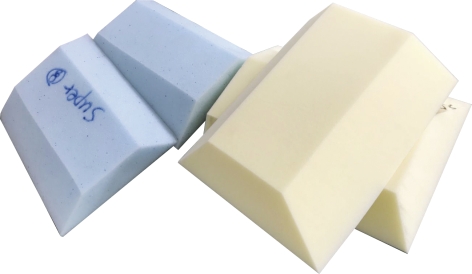

Capable of cutting sponges at any angle between 0 and 175 degrees, accommodating a wide range of design specifications and applications.

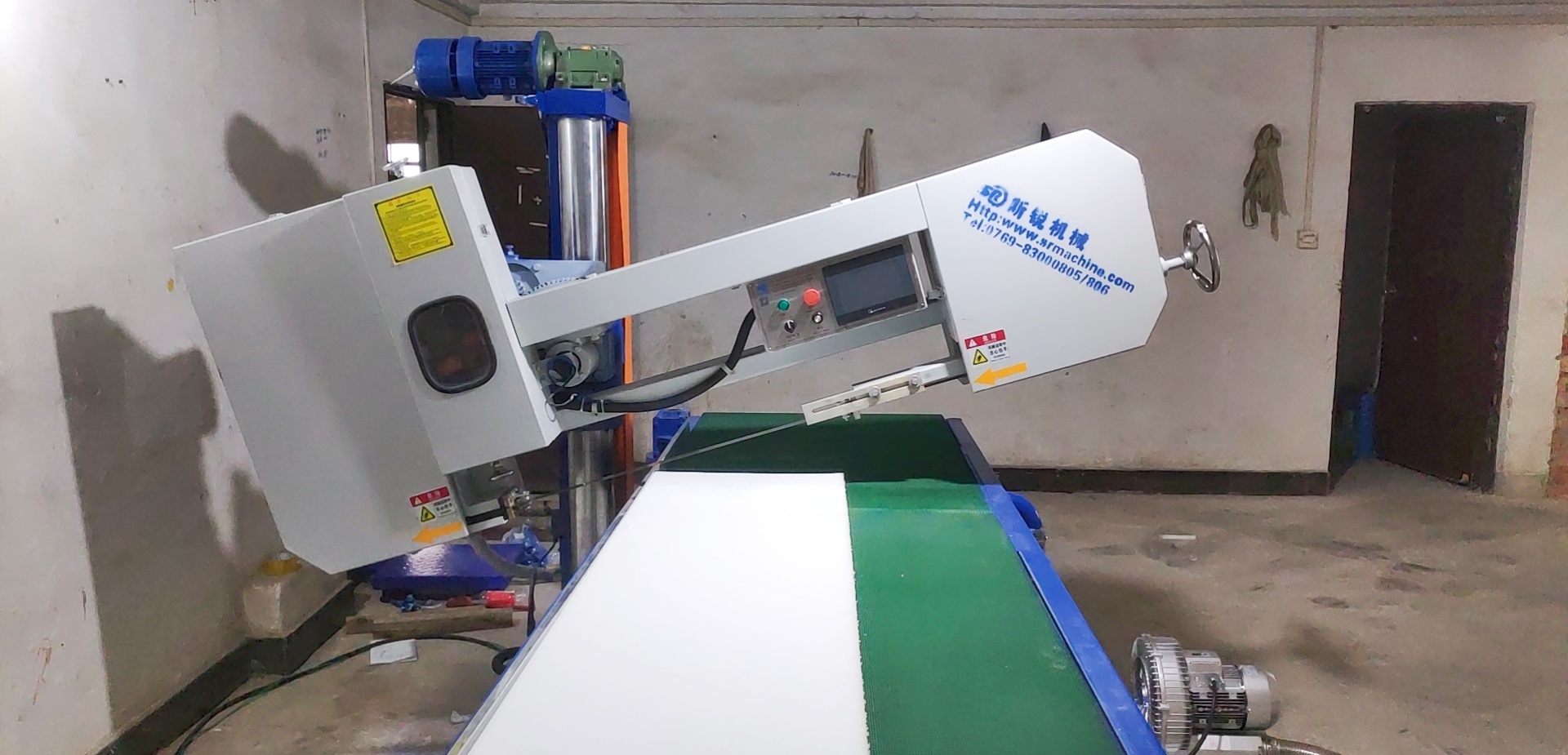

Showcasing the Automatic Foam Angle Cutting Machine, this gallery highlights its precision, automation, and versatility in handling complex foam cutting tasks for industrial and commercial needs.

The SR-A04 Automatic Foam Angle Cutting Machine enhances the efficiency and precision of sponge angle cutting operations. It employs a Programmable Logic Controller (PLC) system that allows operators to digitally input the desired cutting angle between 0 and 175 degrees. Once the angle is set, the machine automatically adjusts to the specified position and executes the cut with high precision. This automation significantly reduces manual intervention and increases productivity, making it four to five times more efficient than traditional angle cutting machines.

| Model | SR-A04 |

|---|---|

| Cutting angle | 0-175° |

| Blade length | L4600MM |

| Total power | 5.49KW |

| Weight | 800KG |

| External size | L2445XW2180XH2200MM |

SR Machines specializes in providing innovative sponge machinery solutions, offering precision, reliability, and efficiency. With expert design, global support, and customer-centric solutions, we enhance production performance and long-term durability.

Continuous R&D investment brings advanced foam processing technology daily.

24/7 technical assistance with rapid parts delivery guarantee.

In-house design and manufacturing delivers exceptional value-driven solutions.

Over ten years advancing foam machinery manufacturing excellence.

Complete foam equipment range from production to packaging solutions.

Comprehensive support from initial consultation through ongoing maintenance.

We provide cutting-edge foam machinery designed for precision, efficiency, and long-lasting durability. Backed by deep industry expertise, global support, and a strong focus on customer-centric solutions, ensuring optimal performance and satisfaction.

Discover top-tier inverters in our product section, each crafted for maximum efficiency and reliability in any setting.

Explore expert insights, industry trends, and the latest updates on innovative sponge machinery solutions, designed to optimize production efficiency, improve performance, and drive sustainable growth in manufacturing processes.

Uncover efficient packing machines designed to streamline sponge product packaging and logistics.

Discover how modern cutting machines are revolutionizing precision in sponge manufacturing processes.

Learn about eco-friendly re-bonding solutions that turn sponge waste into valuable products.

Explore the latest advancements in sponge foaming machinery enhancing production efficiency and product quality.

The cutting speed is relatively fast, with the ability to complete several meters of cutting length per minute. The exact speed varies based on the foam material and thickness.

The cutting precision is high, with an error range of ±0.5mm, ensuring smooth cutting surfaces and precise angles.

The cutting angle range is from 0° to 90°.

Yes, the machine supports batch cutting. The worktable is equipped with a conveyor system, allowing multiple foam blocks to be loaded for continuous cutting, which improves production efficiency and is suitable for large-scale production.

The after-sales service includes equipment installation and commissioning, operator training, routine maintenance, spare parts supply, and technical support. Long-term after-sales service is provided.

The blades should be replaced approximately every one month if the machine operates 8 hours per day. The replacement cycle depends on the foam's hardness, cutting frequency, and blade material.

The warranty period is 1 year, during which free repairs, parts replacements, and other services are provided.

Yes, the fully automatic foam angle cutting machine supports multi-angle cutting.

If a fault occurs, you can contact us for technical support, remote diagnosis, or we can dispatch technicians for on-site repairs.

Yes, the machine supports cutting large-sized foam. Custom worktables can be made according to specific size requirements.

The machine is compatible with a variety of foam materials, including high-density foam, low-density foam, memory foam, rubber foam, and composite materials.

The fully automatic foam angle cutting machine is used for precise angle cutting of foam materials, enabling the creation of various beveled edges to meet the diverse processing needs of foam products.

Yes, we provide on-site installation, commissioning, training, and maintenance services to ensure smooth operations for our clients.

You can reach us via email at sr@srmachine.com or by phone/WhatsApp at +86-13450688517. Our factory is located in Dongguan City, Guangdong Province, China.

Our factory follows strict quality control measures, uses advanced technology, and adheres to certifications such as ISO9001:2015 and SGS/CE standards.

Absolutely! We design and produce tailored solutions to match your specific production requirements.

We specialize in foam machinery, including sponge foaming machines, cutting machines, re-bonding machines, and other custom-designed equipment to meet industry needs.