Usually 2-5 months, depending on the degree of customisation of the equipment.

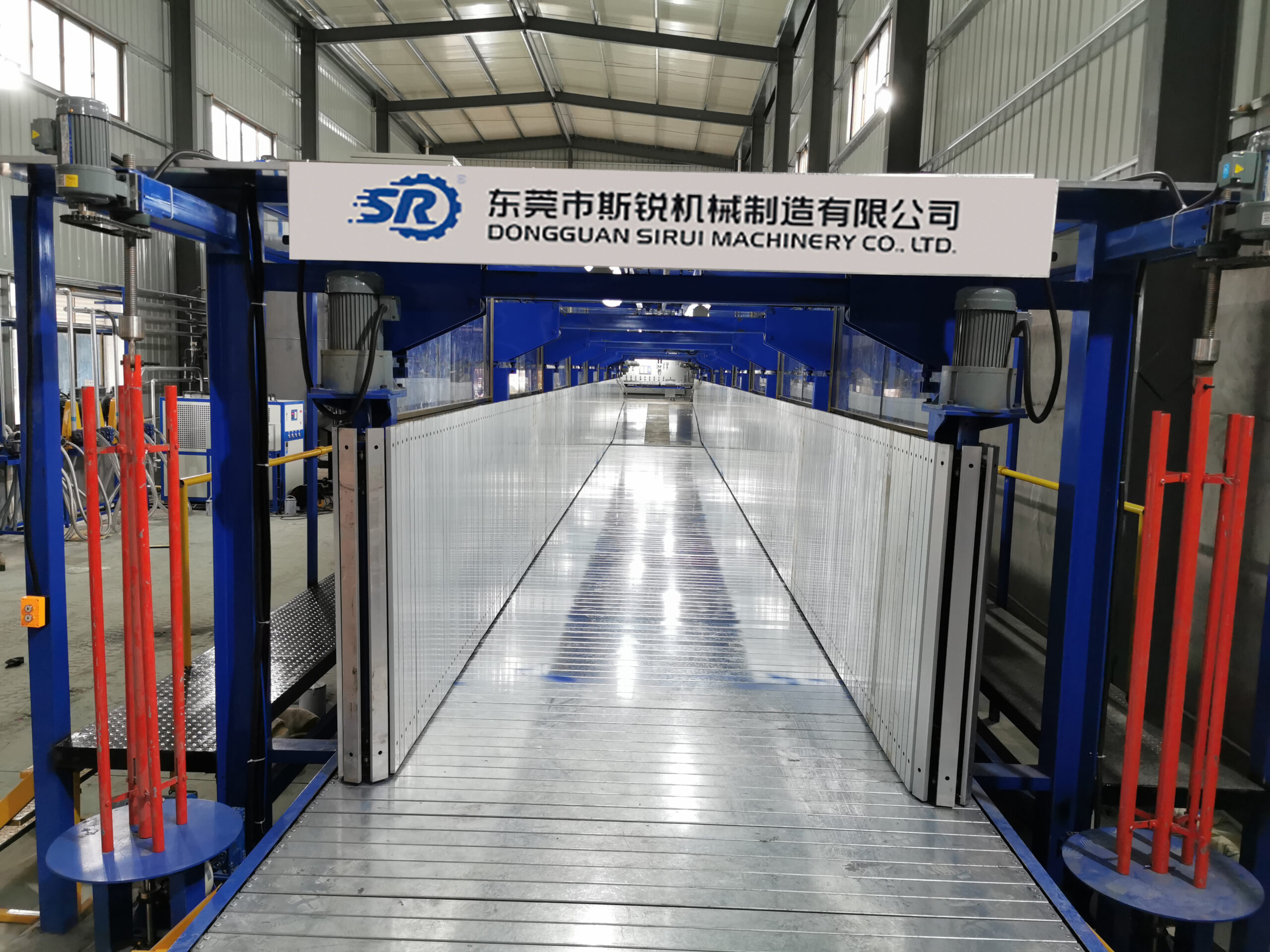

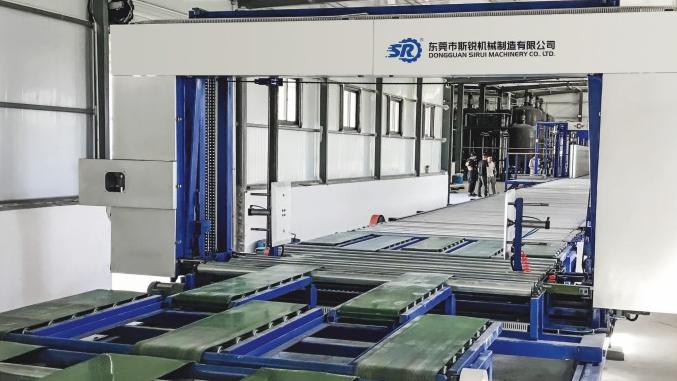

The SR-HCF Horizontal Automatic Continuous Foam Foaming Plant efficiently produces sponges with densities from 4 to 180 kg/m³. It features a high level of automation, a flexible touch screen control system, storage for up to 10 formulations, and remote control via the Internet, ensuring scientific and visual cost management. This versatile machine serves industries such as furniture, apparel, footwear, and electronics.

Advanced sponge foaming system featuring automated material mixing, precise control, and efficient cutting, ideal for producing high-quality foam blocks in large-scale manufacturing environments.

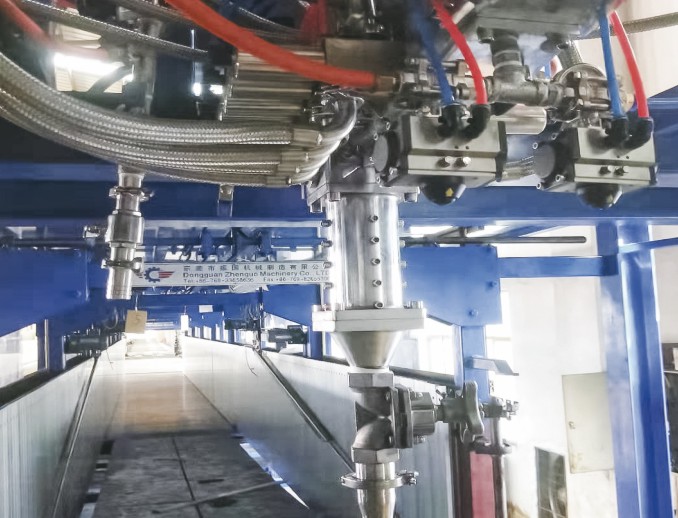

Ensures consistent TDI and MDI pump performance with advanced magnetic coupling technology, eliminating leakage risks and enhancing durability. This innovative design guarantees reliable operation, improved safety, and reduced maintenance, making it ideal for demanding industrial applications requiring precise and secure chemical handling.

Automatically adjusts drop plates for precise width and height alignment, ensuring seamless operation and adaptability. This feature enhances efficiency, accuracy, and flexibility in various applications, reducing manual adjustments and improving overall performance.

Foam blocks are accurately cut into precise sizes post-curing, streamlining the production process for efficiency and consistency. This ensures optimal material utilization and high-quality output for various industrial applications.

This machine is suitable for the production of soft polyurethane foams, high rebound foams, memory foams, super soft foams, and shoe foams with a density range of 5-180kg/m³, primarily producing block and long foam. It uses a highly automated human-machine interface control system, which allows for flexible adjustment of production parameters. It is intended for use in furniture, bust, shoe materials, and automotive industries.

Working Principle:

Usually 2-5 months, depending on the degree of customisation of the equipment.

A standard assembly line usually requires 2-4 operators, including batching, operating and monitoring personnel.

Yes, we do.

Usually the range is 5-180 kg/m³, the formula can be adjusted to achieve different densities according to the needs.

Yes, modern foam lines are often equipped with automated raw material proportioning systems, online monitoring systems and data logging capabilities.

High quality, fine sponge pores and even density distribution.

Including installation and commissioning, technical training, spare parts supply and remote support

Depending on the model and production capacity, the standard 13-component assembly line is 45 metres long, 8 metres wide and 5 metres high, requiring a workshop length of 55 metres or more.

Yes, the speed can be adjusted and the speed range is usually set according to the recipe and product requirements.

Regular cleaning of the mixing head, checking the sealing of the pipeline and the running status of the raw material pump, and comprehensive maintenance is required every 6 months or 1 year.

Yes, it can be adjusted according to the type of sponge to be produced.

Yes, we will arrange on-site training on foaming technology after installation, with 1 density for high and 1 density for low.

Continuous foaming means mixing raw materials and moulding continuously through an assembly line, which is highly productive and suitable for mass production. Intermittent foaming, on the other hand, is operated in batches and is suitable for small-lot or customised production.

1 technician, installation time 30 days (customer needs to arrange 6 people to help)

Yes, the assembly line supports the production of many types of sponges according to the adjustment of raw materials and formulas.

| Model | SR-HCF |

|---|---|

| Foaming group | 13 Groups |

| Foaming type | Sprayer/Trough |

| Foaming width | 1150-2250mm |

| Foaming heigh | 1300mm |

| Foaming density | 4-180kg/m3 |

| Foaming speed | 2000-8000mm/min |

| Max.output | 200-350L/min |

| Mixing head power | 37kw |

| Total power | 130kw |

| Oven length | 18000mm |

| Machine external size | L38000*W4500*H3200mm |

SR Machines specializes in providing innovative sponge machinery solutions, offering precision, reliability, and efficiency. With expert design, global support, and customer-centric solutions, we enhance production performance and long-term durability.

Continuous R&D investment brings advanced foam processing technology daily.

24/7 technical assistance with rapid parts delivery guarantee.

In-house design and manufacturing delivers exceptional value-driven solutions.

Over ten years advancing foam machinery manufacturing excellence.

Complete foam equipment range from production to packaging solutions.

Comprehensive support from initial consultation through ongoing maintenance.

We provide cutting-edge foam machinery designed for precision, efficiency, and long-lasting durability. Backed by deep industry expertise, global support, and a strong focus on customer-centric solutions, ensuring optimal performance and satisfaction.

Discover top-tier inverters in our product section, each crafted for maximum efficiency and reliability in any setting.

Explore expert insights, industry trends, and the latest updates on innovative sponge machinery solutions, designed to optimize production efficiency, improve performance, and drive sustainable growth in manufacturing processes.

Uncover efficient packing machines designed to streamline sponge product packaging and logistics.

Discover how modern cutting machines are revolutionizing precision in sponge manufacturing processes.

Learn about eco-friendly re-bonding solutions that turn sponge waste into valuable products.

Explore the latest advancements in sponge foaming machinery enhancing production efficiency and product quality.

Yes, we provide on-site installation, commissioning, training, and maintenance services to ensure smooth operations for our clients.

You can reach us via email at sr@srmachine.com or by phone/WhatsApp at +86-13450688517. Our factory is located in Dongguan City, Guangdong Province, China.

Our factory follows strict quality control measures, uses advanced technology, and adheres to certifications such as ISO9001:2015 and SGS/CE standards.

Absolutely! We design and produce tailored solutions to match your specific production requirements.

We specialize in foam machinery, including sponge foaming machines, cutting machines, re-bonding machines, and other custom-designed equipment to meet industry needs.