- Home

- »

- Foam cutting solution

Foam cutting solution

Durability

Precision

Compatibility

- All uploads are secure and confidential

meet diverse cutting needs and ensure product size and shape accuracy.

improve production efficiency and reduce material waste

supports cutting of different types of sponges soft, hard, memory foam, etc.

Reduce manual operations and improve process control levels

Short foam sheet cutting

Cut sponge into uniform thin slices, the thickness range is usually 2-200mm, support one-time continuous multi-layer cutting, suitable for mattresses, sofa cushions, packaging materials, etc

SR-HC02, SR-H02

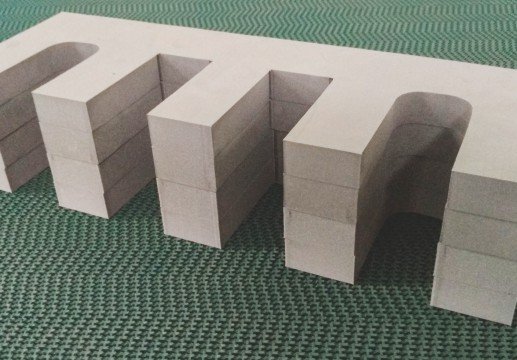

CNC special-shaped cutting

the cutting error isWithin ±0.2mm.

SR-CNC05

Complex shape processing

Supports difficult special-shaped patterns, such as curves, waves, circles and customized graphics.

Automation

No need to manually adjust the path, just input the CAD drawing to complete the cutting, reducing operation time.

Fast processing speed

knotThe combined optimized tool and path planning system greatly improves cutting efficiency.

Continuous production

supportedMulti-task processing can cut multiple complex graphics at the same time to adapt to mass production needs.

Explore Partnership and Purchase Opportunities

- Expert support for machinery needs.

- Reach us via phone/email.

- Visit during business hours.

- Stay updated through online platforms.

- Quick response via contact form.

Insights and Updates

Explore expert insights, industry trends, and the latest updates on innovative sponge machinery solutions, designed to optimize production efficiency, improve performance, and drive sustainable growth in manufacturing processes.

Sinking into a sofa that swallows you whole is no fun, right? Lumpy seats, flat sneakers, and dip-in-the-middle mattresses all

Do you ever toss a smelly kitchen sponge in the trash and feel a tiny pang of guilt? You wonder,

You’ve nailed the perfect foam recipe, stitched the covers, and cured the glue. Now you’re staring at pallets of finished

Picture this: your factory floor is knee-deep in colorful offcuts, and the skip bins overflow faster than snack bowls on

Got a mountain of cushion scraps in the workshop or a warehouse full of dented packaging blocks? You’re probably wondering

Mountains of cushion off-cuts eat warehouse space and rack up disposal fees. You need a smart way to turn that

Frequently Asked Questions

Factory Faq's

Do you offer after-sales support?

Yes, we provide on-site installation, commissioning, training, and maintenance services to ensure smooth operations for our clients.

How can I contact SR Foam Machinery?

You can reach us via email at sr@srmachine.com or by phone/WhatsApp at +86-13450688517. Our factory is located in Dongguan City, Guangdong Province, China.

How does SR Foam Machinery ensure quality?

Our factory follows strict quality control measures, uses advanced technology, and adheres to certifications such as ISO9001:2015 and SGS/CE standards.

Can SR Foam Machinery customize machinery?

Absolutely! We design and produce tailored solutions to match your specific production requirements.

What products does SR Foam Machinery manufacture?

We specialize in foam machinery, including sponge foaming machines, cutting machines, re-bonding machines, and other custom-designed equipment to meet industry needs.