Yes, we provide on-site installation, commissioning, training, and maintenance services to ensure smooth operations for our clients.

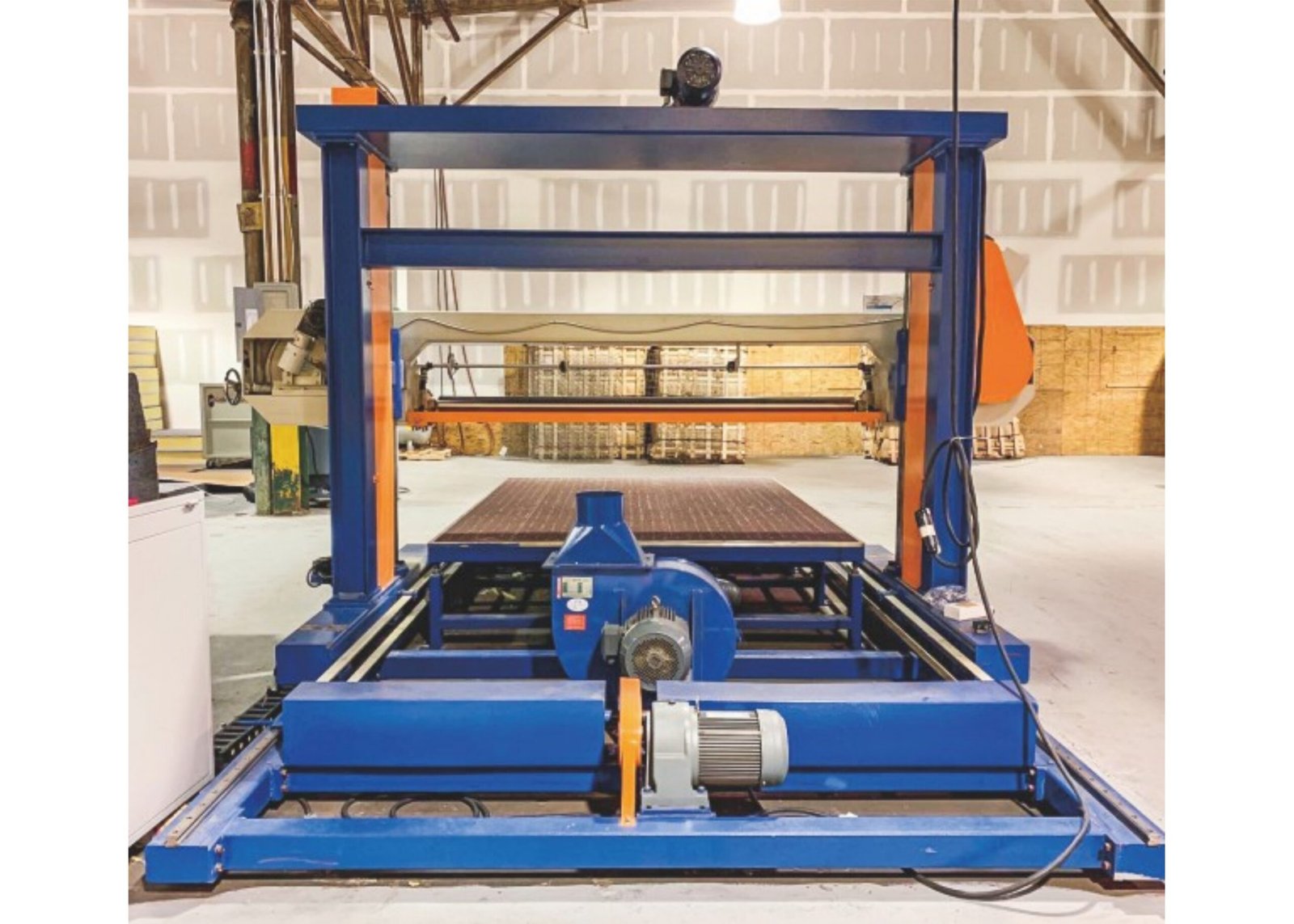

The Horizontal High-Precision Vacuum Cutting Machine delivers exceptional accuracy and stability, utilizing advanced vacuum technology to ensure smooth and efficient foam cutting for diverse industrial needs.

You make the right choice when you choose SIRUI Machinery. As professionals, we manufacture and develop high-accuracy vacuum cutting machines which provide perfection.

Having been able to do this with over 19 years of experience, we know what best works in foam cutting.

Our machines cut foam with millimeter level precision every time you run them.

We use smart vacuum systems, durable blades, and touchscreen controls for smooth operations.

We provide competitive foam cutting machine prices without compromising quality.

Trusted by customers in over 30 countries worldwide.

A High-precision Vacuum Cutting Machine is a smart tool for modern businesses. With clean cuts, reduced waste, and faster production, your work becomes easier and better. At SIRUI Machinery, we help you find the right foam cutting solution at the right price. Whether you need a vacuum foam cutting machine or just want the best foam cutting machine price, we are your trusted partner.

What is a high-precision vacuum cutting machine?

It’s a machine that cuts foam with extreme accuracy using vacuum suction to hold materials in place.

What types of foam can it cut?

It can cut EVA, PE, PU, memory foam, and other soft and semi-rigid foam types.

How much does a foam cutting machine cost?

Prices start around USD 4,900 and vary based on model and features.

Is the machine easy to operate?

Yes, it comes with a touchscreen and user-friendly controls for easy operation.

Do you offer support after purchase?

Yes, we provide warranty, spare parts, and technical support after sales.

| Model | SR-HPV01 | SR-HPV02 | SR-HPV03 |

|---|---|---|---|

| Cutting sponge size | L1500×W1250×H1200mm | L2000×W1620×H1200mm | L3000×W2150×H1200mm |

| Cutting sponge thickness | 1-60mm | 1-60mm | 1-60mm |

| Treading speed | 0-15m/min | 0-15m/min | 0-15m/min |

| Blade length | 6420mm | 7300mm | 8300mm |

| Total power | 15.24KW | 15.24KW | 15.24KW |

| Machine external size | L2000×W2200×H1800mm | L2800×W2200×H2500mm | L3800×W2200×H2500mm |

SR Machines specializes in providing innovative sponge machinery solutions, offering precision, reliability, and efficiency. With expert design, global support, and customer-centric solutions, we enhance production performance and long-term durability.

Continuous R&D investment brings advanced foam processing technology daily.

24/7 technical assistance with rapid parts delivery guarantee.

In-house design and manufacturing delivers exceptional value-driven solutions.

Over ten years advancing foam machinery manufacturing excellence.

Complete foam equipment range from production to packaging solutions.

Comprehensive support from initial consultation through ongoing maintenance.

We provide cutting-edge foam machinery designed for precision, efficiency, and long-lasting durability. Backed by deep industry expertise, global support, and a strong focus on customer-centric solutions, ensuring optimal performance and satisfaction.

Discover top-tier inverters in our product section, each crafted for maximum efficiency and reliability in any setting.

Explore expert insights, industry trends, and the latest updates on innovative sponge machinery solutions, designed to optimize production efficiency, improve performance, and drive sustainable growth in manufacturing processes.

Sinking into a sofa that swallows you whole is no fun, right? Lumpy seats, flat sneakers, and dip-in-the-middle mattresses all

Do you ever toss a smelly kitchen sponge in the trash and feel a tiny pang of guilt? You wonder,

You’ve nailed the perfect foam recipe, stitched the covers, and cured the glue. Now you’re staring at pallets of finished

Picture this: your factory floor is knee-deep in colorful offcuts, and the skip bins overflow faster than snack bowls on

Got a mountain of cushion scraps in the workshop or a warehouse full of dented packaging blocks? You’re probably wondering

Mountains of cushion off-cuts eat warehouse space and rack up disposal fees. You need a smart way to turn that

Do you offer after-sales support?

Yes, we provide on-site installation, commissioning, training, and maintenance services to ensure smooth operations for our clients.

How can I contact SR Foam Machinery?

You can reach us via email at sr@srmachine.com or by phone/WhatsApp at +86-13450688517. Our factory is located in Dongguan City, Guangdong Province, China.

How does SR Foam Machinery ensure quality?

Our factory follows strict quality control measures, uses advanced technology, and adheres to certifications such as ISO9001:2015 and SGS/CE standards.

Can SR Foam Machinery customize machinery?

Absolutely! We design and produce tailored solutions to match your specific production requirements.

What products does SR Foam Machinery manufacture?

We specialize in foam machinery, including sponge foaming machines, cutting machines, re-bonding machines, and other custom-designed equipment to meet industry needs.